The pump redesign is made for the company Band op Spaning, with the goal of creating sustainable, efficient, and aesthetically improved product, which communicates its connection to automotive industry.

The goal of this project is to redesign the existing tire pressure pump, in order to improve it in aspects of sustainability, efficiency, and user interaction. Some of the additional issues with the existing pump are the space and cable mismanagement, difficulty in assembly, and an unreliable locking mechanism. The pump is used for pumping the car tires and is powered by solar panels and the batteries inside the casing.

Before going into form design, space management issue needed to be addressed, as well as adding additional batteries. When the most optimal configuration was achieved, we went into form design and material selection.

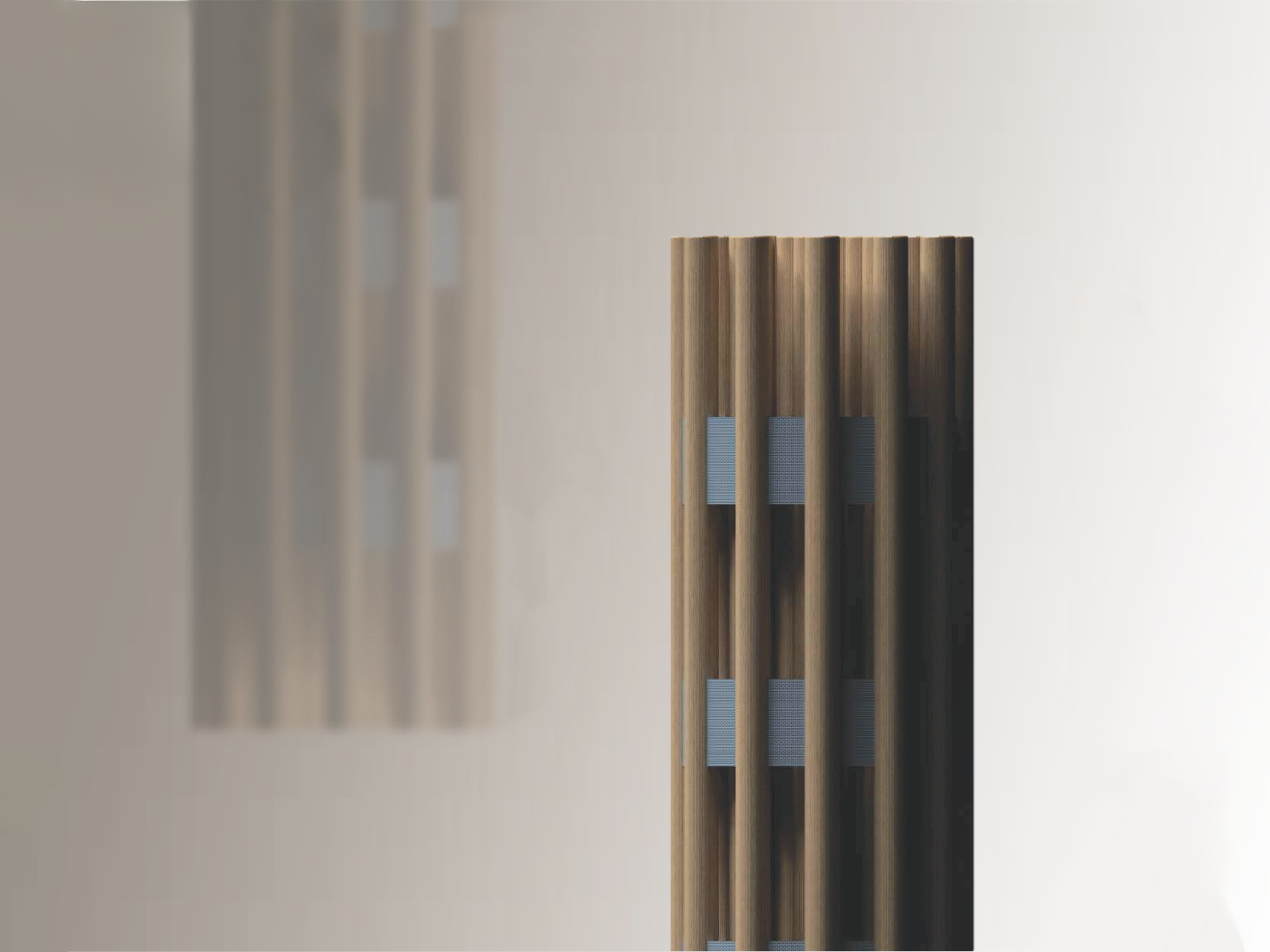

The components are placed on the shelves, on top of each other, in such a way that they are easily accessible in case of any needed repairs or replacements. The chosen material of the outer shells is bio composite, due to its durability, ghapeability, and greater recyclability than the fibreglass of the previous pump.

In between the bio composite casings, the aluminium profiles are placed. Aluminium is chosen due to its durability, and easy manufacturing through extrusion. In this way it is possible to integrate the locking mechanism, as well as slots for shells holding the components. The pump is designed to last up to 20 years, with minimal repairs, therefore the appropriate materials were chosen.

On the front part of the shell, we designed an indent with the purpose of redirecting the hose back into the casing, without the hose hitting and damaging the screen, which is the problem with the current pump.

The curves of the casing are designed to help the product communicate it's link to the automotive industry, whereas the colour is chosen to communicate sustainability and sophistication.

The redesign of the pump was prototyped to give a look and feel of the real envisioned product. The outer shells were made with foam milling, filling and sanding, as well as final painting in the chosen colour, while the inside construction was made with aluminium, and the real components were placed inside.

With the newly redesigned smart tire pump, the user is provided with an easy experience, in an aesthetically and functionally improved product.

Team project - Florine Sreeram, Julie Leclercq, Youp Kroon, Korina Kljaic